Medical facilities are already high-risk facilities in which any particulate matter could lead to infection. The air must be of pristine quality to reduce the risk of hospital-acquired infections and prevent diseases from spreading.

That's even more challenging when construction or maintenance projects take place. As hospitals and clinics continually upgrade and improve their facilities, there is an ever-pressing need for sanitation. And that includes exceptional air filtration to capture dust particles, microbes, and pollutants.

You've likely heard about High-efficiency Particulate Air (HEPA) filters. But they're not just for HVAC systems. Here's how HEPA solutions can help you keep medical facilities clean and sanitary bring construction.

Use an Air Purifier for Dust Containment

Most construction and maintenance projects create dust, which is why an air purifier is a simple yet great solution. Dust particles irritate the respiratory system, which could be quite dangerous for some patients. It lingers on surfaces, trapping pollutants and microbes, and can even carry pathogens through the air. Using air purifiers to remove dust can reduce concentrations of small particles by 30–80%.

Complement Dust Containment with Air Filtration

HEPA filters are a critical part of dust containment systems. They typically work in tandem with a negative air machine that lowers the air pressure in the work zone. Because air flows from high-pressure to low-pressure areas, this prevents particulate matter from leaving the space. It also forces air through the HEPA filter, which traps as much dust as possible.

You can invest in a mobile containment-filtration unit for areas that can't be fully enclosed, such as a hallway. The negative air pressure prevents dust and pollutants from leaving the work area, while advanced filtration keeps the air clean and safe for workers.

If your project is happening in an enclosed space, set up an "anteroom" that reduces the air pressure and effectively isolates the work zone from the rest of the facility.

Avoid Ozone-releasing Purifiers

Some air-purification systems, such as electrostatic precipitators and certain UV sterilizers, release ozone. Even trace amounts can cause respiratory distress, especially for vulnerable patients.

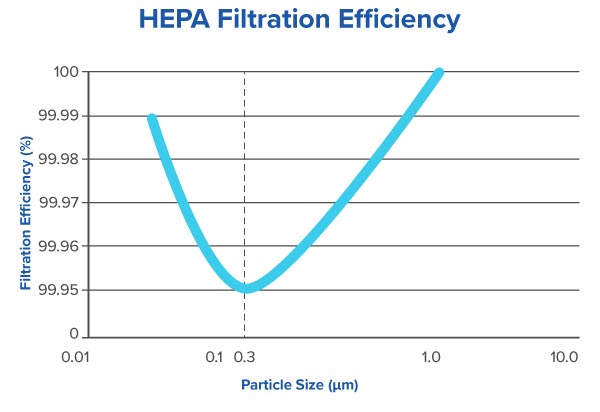

HEPA-equipped dust containment and air filtration devices are much safer for hospitals. Look for a medical-grade filter (capturing 99.97% of particles sized .03 microns and larger).

The system should have a high Clean-air Delivery Rate (CADR) to clean the air as quickly as possible. This, combined with a negative air machine, reduces the risk of microbes escaping the space. Aim for a CADR of at least 300 to 400 cubic feet per minute (CFM) for rooms of the same size. Ideally, the CFM is even higher. For example, a 400 CFM air purifier will purify a 200-square-foot room twice as fast as a 200 CFM system.

Conclusion

The Infection Control Risk Assessment (ICRA) provides clear guidelines for controlling airflow and containing dust, pathogens, and pollutants. You must create negative air pressure in the workspace to prevent particulates from spreading. This also creates an opportunity to force air through the HEPA filter, which can catch microbes and dust particulates down to .03 microns in size.

ICRA guidelines also recommend that you monitor your negative airflow. Ideally, your air purification/dust containment system includes a negative air indicator (manometer), so you can ensure your work area remains isolated.

To keep the facility as safe and clean as possible during construction, ensure that your project meets ICRA standards. Install units at every airflow outlet in the work zone. This may require a combination of barriers, anterooms, and protective covers for access to cables, etc.

Want to learn more? Download the ultimate guide to infection control for dust in a high-risk environment.