Share this

What You Need To Know About Negative Air Machines

by HEPACART on Jul 29, 2020

Negative air machines clean the air and create positive or negative air pressure.

The COVID-19 pandemic of 2020 has generated unprecedented demand for equipment that can convert hospital rooms to negative pressure isolation rooms. Hospitals large and small have been scrambling to come up with enough negative air rooms to accommodate coronavirus patients.

Negative air machines are a key piece of equipment in this scenario, so our goal for this post is to bring together as much useful information as possible. This post is a quick read, so if you haven't learned all you need to know by the end of it, you can follow the links we've provided for more information.

What Negative Air Machines Do

Negative air machines are used to clean the air and create positive or negative air pressure in medical facilities, factories, commercial buildings, job sites, and in confined spaces with mold, asbestos, or lead.

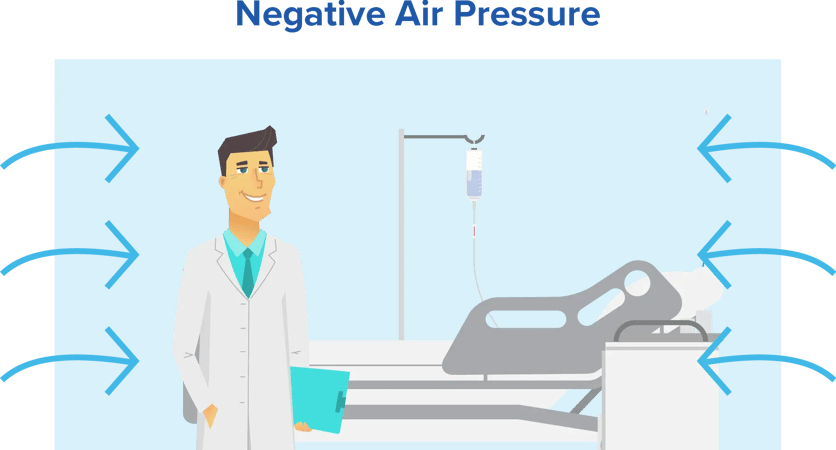

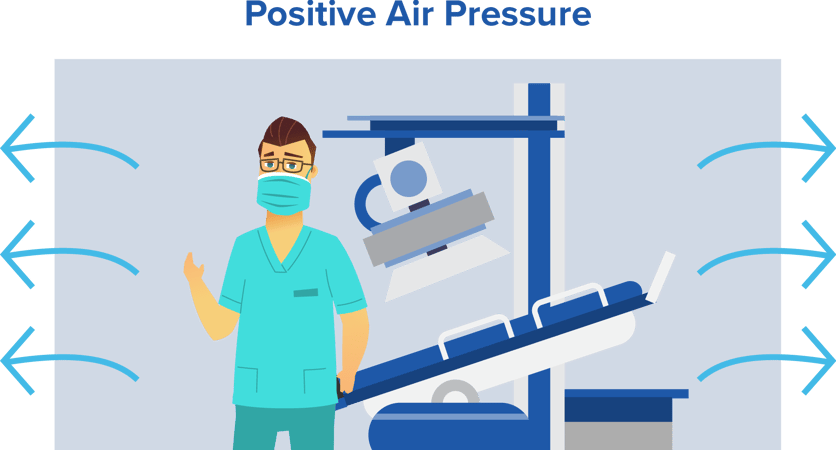

Negative air machines are central to creating safe healthcare environments by not only cleaning the air but also creating positive or negative air pressure. Negative pressure isolates a space and prevents the spread of infectious pathogens from a room; positive pressure protects those inside the room, keeping outside air from getting in and harming immunocompromised patients.

A primary use of negative air machines during the 2020 coronavirus outbreak was to convert single patient rooms to airborne infectious isolation rooms using a fan to force air through a HEPA (high-efficiency particulate air) filter and out of the room. The idea is simple: create lower pressure inside the room, and pathogens will have a hard time escaping into the rest of the facility.

But there are many technologies and protocols involved in reaching a successful execution of that simple idea. Let's start with the component at the heart of any negative air machine: the filter.

Filtration Basics: From ACH to ULPA

Often a negative air machine will be equipped with a prefilter to keep larger particles from getting to the HEPA filter. For example, a prefilter with a MERV (minimum efficiency reporting value) of 8 will be mounted upstream of a HEPA filter with a MERV rating of 18+. This increases the life of the more expensive HEPA filter, thereby lengthening routine maintenance intervals.

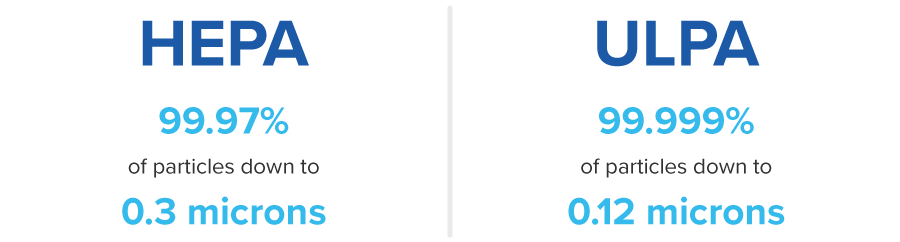

Where does MERV come from — what's its origin? According to the American Society of Heating, Refrigerating, and Air Conditioning Engineers (ASHRAE), it’s the rating for the effectiveness of a filter to trap particles. The higher the number, the finer the particles it traps. HEPA filters carry ratings of 17 and above.

There's even finer filtration available than HEPA, namely ULPA, which stands for ultra-low particulate air, with the top MERV rating of 20. ULPA filters are mostly used for specialized applications. HEPA filters are more broadly used than ULPA filters in healthcare because they're considered optimal for most biological uses.

HEPA filters are also less restrictive than ULPA filters, meaning the fans in negative air machines can more easily draw air through them, which factors into the machine's ability to change the air in the room.

If you know the machine's cubic feet per minute (CFM) rating, and the room's size, you can calculate air changes per hour (ACH). As an example, a 500 CFM negative air machine pulling air from a 2,000 cubic foot room would be 500 times 60 minutes divided by 2000 = 15 air changes per hour.

The Importance of Room Sealing

For effective isolation, a room must be well-sealed. Therefore, prior to installing a negative air machine, use tape to seal air grilles, windows, and any other places where air could be drawn in. The less air leakage, the more efficiently the air pressure differential can be maintained. This means the speed control on the negative air machine can be set lower to maintain a given differential, reducing noise and saving electricity.

Electronic Pressure Monitoring

ASHRAE's Standard 170 requires isolation rooms to have a permanently installed device to monitor pressure differential. Such devices can be simple, such as manometers with liquid in tubes, or calibrated ball-in-tube indicators. However, electronic pressure monitors have several advantages, including greater sensitivity, accuracy, and the ability to trigger alarms at the room and remotely, such as at a nurses' station.

Negative Pressure Room Configurations

The American Society for Healthcare Engineering describes several possible ways to configure a negative air machine. They differ in where they direct the output of the machine after passing through a HEPA filter. Here are three of the configurations.

- HEPA to Corridor: The first option exhausts air to the corridor outside the room. It requires a vestibule, or anteroom, at the entrance of the room, through which the exiting air is ducted. With the anteroom in place, there should be a minimum of five feet of width in the corridor.

- HEPA to Outside: This option requires sealing the return air grill in the patient room and ducting HEPA-filtered air through an exterior wall or window to the outside.

- HEPA to Return: ASHE's third option is to duct HEPA-filtered air to the return air grill of the hospital's HVAC system. This requires sealing the remaining part of the grill.

Buying or renting a Negative Air Machine

You may need a negative air machine for room isolation because of contagious viruses — which has been our focus in this post — or for dust control in construction in conjunction with an anteroom, mobile dust containment cart, or airborne pathogen disinfection module.

Regardless of your application, it's important to compare before you buy, because you'll find some real differences in quality, efficiency, and features when reviewing negative air machines from different manufacturers.

Here are some advantages of HEPAFORCE® negative air machines.

- Multiple flow and leakage tests mean every unit arrives tested, certified, and ready to work.

- Every unit is equipped with a MERV 18-plus HEPA filter.

- Optional MERV 9 prefilters and carbon filters available depending on need.

- High-quality ECM fan motors move more air with less electricity than other motors.

- Up to three 120-volt HEPAFORCE® 1100s can run on one 15-amp circuit.

- Quiet, long-life fan motors have variable speeds from 50 cfm to 1000 cfm.

- Filters can be changed easily without tools.

- All units have standard 12-inch inlet and outlet.

HEPAFORCE® Air Negative Air Machines are available for purchase and through our nationwide HEPACART® Rental Program. Renting is for short-term and limited-capital projects and infection control solutions.

Resources

- Planning and maintaining hospital air isolation rooms

- Negative Pressure Patient Room Options (ASHE)

- What is a MERV Rating?

- Common Problems with Negative Air Machine Setup

- How to Properly Set Up Your Negative Air Machine

- Why Mold Abatement Requires Negative Air Pressure & HEPA Filtration