Share this

What Every Facility Manager Should Know About HEPA Filters

by HEPACART on Jun 09, 2021

The primary goal of HEPA filtration in buildings is to keep the air clean and quality high.

Let’s take a trip down HEPA filter lane since its founding profoundly impacts why and how we filter and clean indoor air. We’ll start with the deadly-serious beginnings of the HEPA (high-efficiency particulate arrestance) filter, developed in the 1940s to remove irradiated dust from the air in nuclear facilities. Around that time, it first became clear that potentially irradiated dust particles and moisture had to be removed from the air in nuclear facilities.

To condense a decades-long story, HEPA filtration in medicine, manufacturing, public spaces, and private homes followed, and today the term “HEPA” has become a huge marketing tool — to the point that buyers of air purifiers and vacuums must be wary of equipment using inferior filters being advertised as HEPA-like, HEPA-type, or HEPA-ready.

Even when using medical-grade equipment equipped with certified HEPA filters, you should make sure that the entire unit has been tested to account for possible leakage past the filter or for incorrect filter sizing.

What is a HEPA Filter?

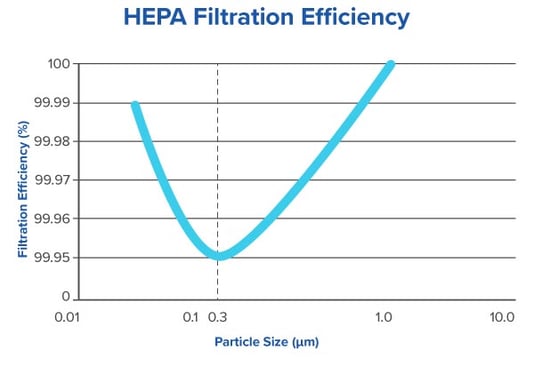

The U.S. Department of Energy HEPA standard requires that a filter remove at least 99.97% of particles with a diameter of 0.3μm (micrometers, or one-millionth of a meter) from the air that passes through it. A micrometer — also called micron — is ridiculously small. For perspective, a human hair is about 50µm in diameter. Think about what an accomplishment it is to create a filter capable of catching particles that small the next time you compare prices of HEPA filters to lesser filters.

The reason 0.3µm was chosen for the standard is that it’s the most difficult size to filter out. Smaller particles are so light that they are subject to Brownian motion, moving erratically because they're busy colliding with gas molecules. This means they'll crash into the randomly-aligned glass or synthetic fibers of the filter and stick to them, a process known as diffusion.

Particles larger than 0.3µm are so heavy that their inertia carries them straight into fibers (impaction), or their diameter causes them to become stuck between fibers (interception).

Source: National Institute for Occupational Safety and Health (NIOSH)

To sum up, diffusion captures the teensy weensy particles, straining or impaction captures the big ones, and some combination of the two gets the medium-sized ones.

Where Are HEPA Air Filters Used?

A registered trademark early on, HEPA later became a generic term for filters that meet the DOE standard. Typically HEPA filters are found in cleanrooms for electronics manufacturing, medical devices, food and pharmaceutical production, healthcare environments, homes, and cars.

One thing HEPA filters are not designed to do is filter out gases, a job better left to activated carbon filtration or carbon cloth filters. For example, volatile organic compounds (VOCs) are airborne chemicals that HEPA filters can't touch. VOCs derive primarily from building products and materials and cleaning products.

Speaking of other types of filters, often HEPA filters are paired with a less expensive pre-filter upstream that removes larger particulates, lengthening the useful life of the HEPA filter. Some pre-filters have an activated carbon component.

Healthcare facilities may not use HEPA-filtered HVAC systems. Only protective environment rooms are required by code to be equipped with HEPA filters, be it at the air terminal or through in-room equipment. For this reason, it makes sense to use a stand-alone air scrubber, air purifier, or negative air machine.

HEPA Filters in Your Facility

The need for HEPA filtration in hospitals and other healthcare facilities comes from the fact that bacteria, mold spores, and pathogen-laden dust particles are constantly a threat to those with less-than-healthy immune systems.

Regular filter changes are critical because the HEPA filters themselves can become hazardous. For example, mold spores are caught by HEPA filters but may remain alive on the surface. Other contaminants caught by the filter can then act as nutrients, allowing mold spores eventually to grow through the filter and release new spores.

This danger can be mitigated by changing filters on the recommended schedule. That may be tough for the busy facility manager on a tight budget since HEPA filters are expensive and, uh, yes, out of sight. But the alternative is turning the means of creating safe air into an additional hazard.

In a hospital, applications for equipment that uses HEPA filters include the following:

- Infection control and prevention

- Emergency preparedness

- Construction projects / renovations

- Maintenance

Other healthcare operations, such as urgent care, long-term care, medical labs, and pharmaceutical manufacturing need HEPA filtration to safeguard the health of patients and staff. There are plenty of non-healthcare industries that rely upon HEPA filtration equipment, too, including but not limited to data storage centers, hospitality and casino, research facilities, and schools.

Explore HEPAFORCE Equipment

Whether your concern is reducing viral load in a particular area, preventing construction dust from spreading pathogens, or controlling dust and spores during routine maintenance that involves removing ceiling tiles, there's a piece of HEPA-filtration equipment designed to help. For example, our HEPAFORCE® AIR Negative Air Machines & Scrubbers help control contaminated air by creating lower pressure to keep it from escaping a room. In the process, they use HEPA filters to clean the air that is pumped out of the room. For a secondary level of protection against pathogens, you can add the UV-FORCE® Airborne Disinfection Module.

For example, our HEPAFORCE® AIR Negative Air Machines & Scrubbers help control contaminated air by creating lower pressure to keep it from escaping a room. In the process, they use HEPA filters to clean the air that is pumped out of the room. For a secondary level of protection against pathogens, you can add the UV-FORCE® Airborne Disinfection Module.

Our HEPAFORCE® GermBuster room air purifier with UV-FORCE® will disinfect a 3,200-cubic-foot room six times per hour while using 40% less electricity than similar units. Its combination of HEPA filtration and disinfection with far-UVC light pulls in dirty air and scrubs it of most particulates, rendering what's left non-infectious. It could serve as a beneficial supplement to the HVAC system, removing some of the filtration burden during allergy season and cold/flu season.

Our HEPAFORCE® GermBuster room air purifier with UV-FORCE® will disinfect a 3,200-cubic-foot room six times per hour while using 40% less electricity than similar units. Its combination of HEPA filtration and disinfection with far-UVC light pulls in dirty air and scrubs it of most particulates, rendering what's left non-infectious. It could serve as a beneficial supplement to the HVAC system, removing some of the filtration burden during allergy season and cold/flu season.

Finally, the product after which our company was named, HEPACART®, is a dust containment cart for ceiling and wall maintenance projects. It is safer and more effective than jerry-rigged wood frames with plastic sheeting, and it's reusable. Like the other equipment mentioned here, a HEPA filter is at the heart of its effectiveness.

To learn more about how HEPA-filtered products can help make the air at your facility safe and clean, click here to explore our HEPAFORCE equipment.

Resources