Patient safety is critical in any healthcare setting, and one important part of that is preventing hospital infections. There is never enough you can do to prove that infection control and containment are a top priority. While contact transmission is the most common for hospital-acquired infection, airborne transmission is certainly still a concern. Negative air machines can assist with containment of these dangerous airborne particles.

The Cost of Hospital-Acquired Infections

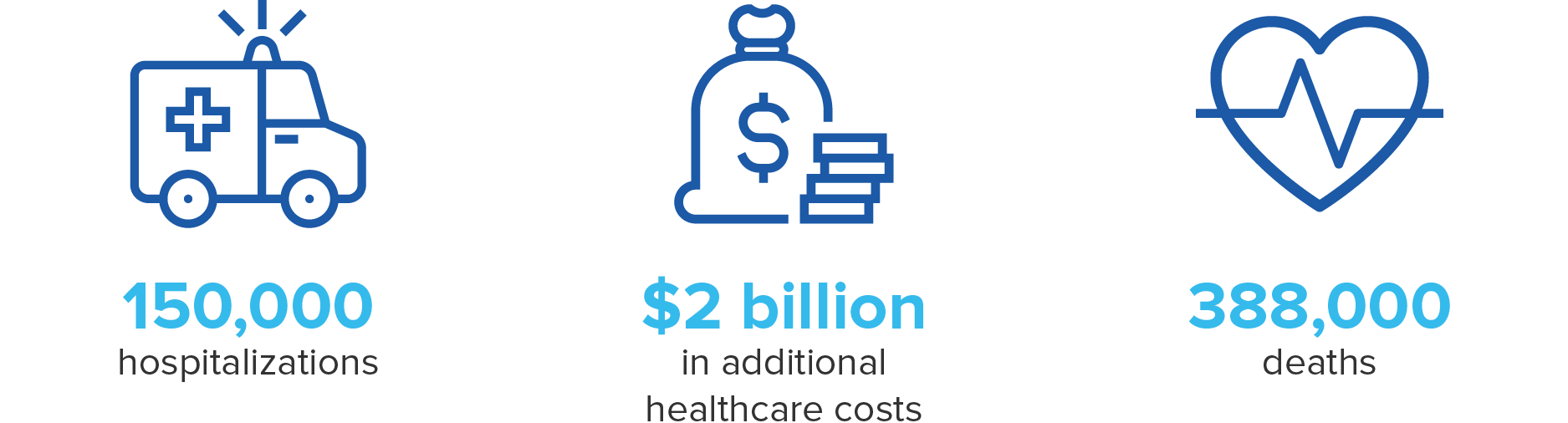

Hospital-acquired infections are a major patient safety concern around the country, for good reason. According to the Centers for Disease Control and Prevention, an estimated 1.7 million hospital infections cause or contribute to around 388,000 deaths each year, including instances of pneumonia, bloodstream infections, and surgical site infections.

The cost is not only apparent in terms of lives affected, but also in costs incurred by healthcare facilities. While hospital infections often necessitate a long stay for patients, those stays are rarely charged at the full cost of treatment. Implementing patient safety protocols that can help to prevent these types of infections not only contribute to better patient outcomes, but also to more profitable facilities.

How Negative Air Machines Work

A negative air machine creates a pressure differential between two different areas. In its natural state, air wants to move from higher-pressure areas to lower-pressure areas in order to reach equilibrium. Negative air pressure machines use this natural inclination to the advantage of infection control.

As an isolation technique, an air machine uses a fan system to force air out the isolated area and through a HEPA filter before it is exhausted into another area of the facility. By controlling the pressure differential with a negative air machine, the facility is able to ensure that all air leaving the isolated room is filtered and clean before it comes into contact with any other patients, thereby lessening the chance of spreading infection.

Where to Use Them

According to the World Health Organization's guide "Prevention of hospital-acquired infections," negative air pressure is recommended for contaminated areas. Creating negative air pressure in a patient isolation room, or in a place where dust and debris are being created, the air that is able to flow out around doors and windows is minimized, keeping patients throughout the facility safer while clean air from outside the room is still able to filter in. In specific terms, the American Institute of Architects recommends that air pressure be 0.01" water gauge (w.g.) or 2.5 Pascals (Pa) for all patient rooms and 0.03" e.g. (8 Pa) for advanced protected environments.

Are They Enough?

Air machines can be extremely effective in minimizing the instance of hospital acquired infections by preventing the spread of contaminated particles, from patient to patient as well as from construction and maintenance sites within healthcare facilities. The best options for maximizing the efficacy of a negative air machine is to utilize it along with other isolation precautions, such as a portable anteroom and HEPA-certified air filters.

Overall, air machines are an important tool when it comes to preventing hospital-acquired infections, but using them on their own is not enough. Patient safety protocols must be strictly enforced. The combination of those processes along with the right technology can offer major benefits to a facility, and most importantly, to its patients.

Our HEPAFORCE® air filtration and purification equipment can filter and clean the air up to 99.97%. Learn more by reading more related articles.