Share this

4 Ways to Control Airborne Contaminants & Dust in Healthcare Settings

by HEPACART on Oct 10, 2019

Updated on August 13, 2020.

Discover common airborne contaminants that cause problems in healthcare facilities and how to eliminate them.

Exposure to toxins or infectious substances in the workplace can occur through inhalation, absorption through the skin, or ingestion. Inhalation makes us vulnerable to one of the biggest dangers in healthcare settings: airborne contamination from dust launched into the air during hospital maintenance or construction activities.

This post touches briefly on four ways to control some of the most common airborne contaminants that cause problems in healthcare and long-term care settings, and should serve as a useful guide as you think about which technologies to use in your facility.

Infection Control for Airborne Contamination #1: Dust Containment

The first step in getting control of air quality hazards is to prevent dust stirred up by maintenance or construction activities from escaping into the rest of the building. In increasing order of project size, the solutions we’ll discuss are:

- Dust containment carts at small openings in ceilings and walls for maintenance.

- Anterooms to seal off entrances to rooms in which dust is being generated.

- Barrier wall systems to seal off large areas under construction.

The increasing use of dust containment carts for hospital and cleanroom maintenance can be attributed to the awareness that when ceiling tiles are disturbed, dust gets launched. Also, mobile carts address the need for a neat and professional-looking workspace that can be moved from location to location quickly and efficiently. The HEPACART® Mobile Containment Cart incorporates a negative air machine with HEPA filtration and is designed to accommodate the need for ICRA Class IV compliance.

An identical model but without the embedded negative air machine, the HEPACART DUSTBUGGY® retains the benefit of being more portable and sturdy than plastic tent enclosures, and can be upgraded later if the need for airflow management arises.

Both the HEPACART Mobile Containment Cart and the DUSTBUGGY models incorporate pass-throughs to allow cable and pipe into the workspace without opening a door.

Another useful containment measure is a small device called a cabling access point (CAP) that can be installed in a standard ceiling tile opening to expedite wire pulling. The HEPACART CAP is a patented productivity tool that provides a 2"x2" ceiling slot with steel rollers that allows cable to be pulled quickly and cleanly into the ceiling space.

An anteroom isolates an entire room when placed over an existing door or opening. The HEPACART AnteRoom installs in less than five minutes and has adapters for connection to a negative air machine on either side of the door for ICRA Class IV compliance.

Temporary walls are used to enclose larger projects. STARC® Systems customizable wall barriers form an airtight seal, interconnect with some other wall systems, and can be erected quickly. STARC RealWall™ barriers have a foam core that provides sound attenuation. For applications where that's not a priority, the company's LITEBARRIER™ walls cost 40% less while still being sturdy, attractive, and air-tight.

All of HEPACART’s dust containment and air infection control solutions aid compliance with stringent indoor air quality precautions such as those outlined in the ICRA Matrix.

Infection Control for Airborne Contamination #2: Airflow Management

Sometimes simply providing a barrier is not enough. Negative air machines such as HEPACART HEPAFORCE® create a negative pressure environment that keeps contaminated air from escaping a room or work area. Somewhat counterintuitively, they do this by piping air out of the room. This exhausted air is run through HEPA filtration that removes spores and dust particles, protecting the surrounding areas of the building from contamination.

Air changes per hour (ACH) must be calculated to determine the airflow capacity of the negative air machine. In hospital environments, you must construct a containment area that completely changes the air in the room between 6 and 12 times an hour, which requires selecting negative air machines with sufficient capacity. Negative air machines can also be used to provide a positive pressure environment in operating rooms, where patients must not be exposed to germs from the rest of the facility.

To understand this topic better, see Air Changes Per Hour, Infection Control, and Dust Containment.

Infection Control for Airborne Contamination #3: HEPA Filtration

Disturbed ceiling tiles are a source of healthcare-associated infections (HAIs) caused by spores of environmental fungi inhaled by infants, the elderly, and immunocompromised patients such as burn patients. Without superior filtration, protecting such patients would be a daunting task.

A dust containment cart with a built-in negative air machine, or a stand-alone machine coupled to an anteroom or a barrier wall, uses a high-efficiency particulate air (HEPA) filter to provide that protection. As defined by the U.S. Department of Energy, a HEPA filter must trap 99.97% of particles 0.3 micrometers (µm) in diameter. Because most dangerous air contaminants, such as dust, spores and many bacteria, are larger than 0.3 µm, HEPA filter works effectively.

But what about pathogens that are smaller than 0.3 micrometers? To truly protect patients and healthcare workers, something beyond the mechanical filtration provided by HEPA filters is needed.

Infection Control for Airborne Contamination #4: Far-UV Sterilization

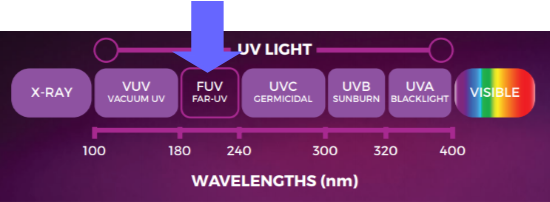

Scientists have known for decades that short-wavelength ultraviolet (UV-C) light kills bacteria and renders viruses inactive. But this ordinary UV light also is a health hazard that can lead to skin cancer and cataracts, so it is not suitable for public areas. That's where Far-UV-C comes in, with a wavelength confined to a narrow part of the UV-C spectrum that cannot penetrate the dead outer layer of skin or the outer tear layer of the eye. Using higher photon energy, far-UV is also more effective at destroying pathogens.

The HEPACART UV-FORCE Air Disinfection Module destroys pathogens using Far-UV lights. This includes measles, tuberculosis, influenza, and other viruses <.3 microns that pose a challenge to its medical-grade HEPA filters. This single-pass duct system featuring far-UVC cleans air to 99.99%. The UV-FORCE can be used on its own or in conjunction with the AnteRoom, DUSTBUGGY, or UV-FORCE Air Disinfection Module.

It is essential as a secondary level of protection, removing viruses such as those that cause measles, tuberculosis, and influenza that are small enough to pass through a HEPA filter. Far-UV sterilization is an important tool for meeting ICRA Class IV standards.

Summary

There is no question that healthcare facilities managers must maintain a vigilant watch over their facilities to decrease the occurrence of these types of infections. To learn more about infection control solutions, read our guide, Infection Control for Facilities Managers. In this guide, we included the best advice from infection control specialists, highly regarded facilities, and notable infection control journals to compile this reference.