Share this

Revolutionizing Dust Containment: 4 Top Tools for Construction in Healthcare

by HEPACART on Jan 29, 2024

Even in the normal day-to-day operation of a hospital or medical center, controlling dust and airborne debris can be a challenge. Add in the chaos that can come along with a construction or renovation project, and you’re in for an even more intense situation with higher levels of filtration needed. Imagine — your teams are opening up walls, completing demolition, or getting up into the ceiling spaces as a part of your renovation. With all the commotion, dust and debris become disturbed and airborne. These particles are inherently more dangerous because you’re now talking about construction dust or ceiling debris in addition to just organic material. For those — patients or staff — who are sensitive to air quality, these projects can cause major irritation or infection if dust containment is not handled strategically.

In this blog, we’re dedicated to showing you how powerful equipment, particularly from HEPACART®, makes dust containment not just effective but surprisingly easy. Whether you’re dealing with sawdust, plaster, or volatile organic compounds (VOC), the right air tools can transform the way you handle these challenges. Let's dive into the world of advanced dust containment and see how high-efficiency HEPACART equipment can meet your needs and empower your facility with safety.

Construction is Inevitable; Dust Doesn’t Have to Be

Construction projects and routine maintenance simply cannot be avoided, but you can always prepare for these disruptions and plan to keep your facility safer through the process. During construction projects, various activities — cutting, demolishing, or otherwise altering materials — can generate dust particles, including plaster, sawdust, and even mold spores. It isn’t just about the visible mess, either. These particles pose serious health concerns and can linger for long stretches when no proper filtration is in place. Preventing dust from negatively impacting your facility is essential, and while opening windows and regular cleaning are good starting points, your facility needs more powerful methods to eliminate dust particles effectively.

Investing in the Best Tools to Limit Dust in Healthcare

Creating a plan to contain dust and improve indoor air quality is only half of the equation for truly keeping the spread of infection at bay. The equipment and tools that you select for your facility are a large contributor to how successful you’re able to be in protecting your patients and staff from harmful particles.

First, you’ll want to ensure that your goals are clear from the start. Are you looking to boost an existing dust containment plan? Do you need to ensure compliance with Infection Control Risk Assessment standards? Whatever you’re hoping to accomplish, make sure the intent is clear from the beginning.

Next, consider the measurable outcome you need from the equipment you choose. Different machines will have differing specifications and results — make sure that your needs and the abilities of your new equipment are aligned. If you’re looking for increased air changes per hour, you might consider an air filter or a dust containment cart with this capability. Do you need to limit the spread of contaminants? An anteroom might be your best solution.

Once you know the type of equipment that will best serve your facility, you must choose your machinery provider. Think about the capabilities, certifications, and longevity of the company that you decide to work with. Beyond that, consider the logistics of your purchase, including payment options, delivery proximity, and ongoing support after your purchase is complete.

4 Essential Tools for Superior Dust Containment

While regular cleaning and generally blocking off affected areas of your facility is a good place to start, these practices are simply not enough when the health of patients and staff is on the line during a construction or renovation project. With airborne particles that are increasingly more harmful, you’ll want to take precautions to maintain a safe indoor air quality for everyone inside. The best way to keep irritation and infection at bay is with a powerful lineup of equipment that is built to promote safety through these types of disruptions in a medical center.

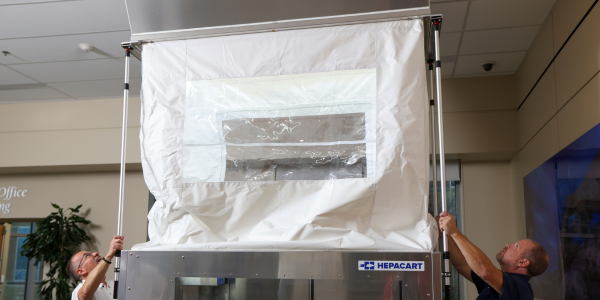

1. HEPACART® Classic

Gone are the days when setting up for ceiling access work was a time-consuming chore, involving makeshift tents and inefficient blowers. HEPACART's dust containment carts, particularly the HEPACART Classic, have revolutionized this process from start to finish. With its user-friendly design, this cart allows for a rapid and efficient setup, reducing the time required for both setting up and taking down by more than half. For your facility’s construction projects, this means less time spent preparing and more time getting the job done.

The HEPACART Classic is meticulously engineered for the rigors of real work in a variety of sensitive settings. Manufactured with robust, easy-to-clean aluminum, this dust containment cart requires no assembly before use, ensuring you can get to work immediately. Even better, the HEPACART Classic can easily be wheeled from one area to the next, ensuring that your facility can have nearly instant dust containment whenever you need it. Whatever work you’re managing, from ductwork to electrical projects, this is one piece of equipment that is a must-have in your medical center.

2. Cabling Access Points:

For many types of construction or renovation projects, your to-do list may involve moving, adjusting, or checking wiring found in the ceilings of your facility. Whether you’re dealing with Ethernet cables, optical fibers, or electrical wiring, this process can be particularly disruptive when you’re talking about moving wiring between high-risk areas of a medical center. Loose debris, accumulated dust, and other potentially harmful substances are easily disturbed and knocked down into sensitive patient areas. CAPs, or Cabling Access Points, offer a solution by creating secure access to pull cables and wires down from the ceiling while also greatly limiting the amount of dust and debris that is pulled down into the hospital environment. These simple yet powerful tools make the process of wire pulling much more efficient while also protecting the environment below. For any project where you’re opening up the ceiling to complete work on wires and cabling, CAPs are a great addition to your lineup of equipment.

3. AnteRoom Classic

For specialized construction, demolition, or renovation within specific rooms of a healthcare facility, an anteroom serves as an essential tool for maintaining a safe, controlled environment. An anteroom creates a sealed-off area, ensuring that dust, debris, and potentially harmful airborne particles are confined to the workspace, preventing their spread throughout the facility. Depending on your specific needs, an anteroom can also provide an almost instant overflow isolation room when your existing isolation rooms are full.

Essentially, it can provide a protective barrier against whatever your most pressing threat is, whether it be the spread of construction debris or a potentially infectious disease. What exactly does an anteroom do? In architectural terms, it acts as a transitional space, similar to how a vestibule functions in buildings, separating two distinct areas. For a medical facility undergoing renovations, the anteroom establishes a protective barrier, much like a seal, between the active construction zone and the rest of the facility. This barrier is crucial for maintaining indoor air quality and ensuring that patient areas remain unaffected by construction activities.

4. STARC® Systems RealWall™:

When the project is larger than just one room or space, STARC® Systems RealWall™ containment walls offer a more robust solution than temporary walls made of plastic sheeting or drywall. These walls provide a secure, efficient, and reusable way to isolate construction zones. While these containment walls do create a separation barrier for infection control and dust containment, they also create an effective barrier for visual distraction in a medical center where every moment — and every ounce of focus — matters. Patents may hear construction activities, but they won’t have to watch the activity happen in front of them. Similarly, staff won’t be as distracted by the bustling of construction workers when the activity is contained in one area with containment walls.

Practically Ensuring Safe Air Quality During Construction

No matter what kind of maintenance, construction, or renovation project your facility has going on, dust containment should be at the top of your list when it comes to keeping your facility safe. It’s not just about keeping thighs tidy and clean. Dust particles and construction debris notoriously contain a higher percentage of infectious and potentially harmful contaminants. Because of this, controlling dust is about much more than aesthetics — it’s about maintaining a safe and healthy environment for everyone who walks through your facility’s doors.

Without proper containment, especially during ceiling access work, the risk of spreading bacteria, viruses, or other airborne pathogens increases significantly. Infection control and facilities managers must be particularly vigilant about controlling hazardous air particles. Using a strategic combination of HEPACART products offers a wide variety of unique solutions to meet the critical needs of any type of construction activity.

Get Your Solutions For Healthcare Construction

Effective dust containment in construction doesn’t have to be overwhelming. With tools like dust containment carts, CAPs, anterooms, and containment walls, containment dust and maintaining air quality becomes a manageable, streamlined process. Remember, the right equipment not only simplifies dust containment but also enhances safety and efficiency in your facility.

Not sure where to begin or how to best support your existing dust containment plan with the equipment detailed in this blog? Reach out to our sales team today to discover the equipment lineup that is right for your facility’s needs and budget.