Share this

Best Cable Pulling Tools for Drop Ceilings

by HEPACART on Nov 11, 2021

Incorrect overhead cable pulling can cause damage. Avoid problems and save time with the right tools.

Electrical contractors, healthcare facility directors, and school facilities managers should use wire pulling tools designed to prevent damage and increase efficiency. While we addressed some of these wire pulling tools in an earlier article, there are a few more that we'd like to highlight that would be beneficial.

We will confine our focus to the realm of low-voltage cables such as Cat 5, CATV, and alarm wiring above drop ceilings that can be hand-pulled. We'll leave high-voltage AC power lines that must be pulled through conduit, aided by special lubricants and industrial-strength pullers for another time.

Preparing for the Pull

What's involved in pulling cable in a drop ceiling? Whether it's large or small, there are some basic steps to follow:

- Figure out what's being connected to where, of course.

- Specify the right cable for the environment (plenum-rated, for example, if the area above the drop ceiling is an HVAC plenum).

- Establish a cable route.

- Install hardware to support the cable.

- Take into account the pull strength and bend radius of your cable prior to setting up a ceiling access panel, cable reels, and access point rollers or funnels.

- Label cables (e.g., if telecom, follow ANSI/TIA/EIA 606-A).

- Position technicians and start the pull.

Let's look at some cable pulling tools that you'll need to accomplish these steps.

Understanding Data Cable

For successfully pulling data wires, the most important tool is your tech, who understands the difference between data cables and power wiring. The former are fragile, require a gentle bend radius, and crush easily (especially fiber optic). When fastening to support hardware, hook-and-loop straps are less likely to damage fiber optic cable than plastic zip ties (you can use zip ties if they're installed loosely).

A basic rule to keep in mind when installing support hardware for low-voltage wires is to maintain an 8-inch separation between unshielded low voltage communications cable and 120V or 240V power cables when running parallel to them (per National Electric Code/National Fire Protection Act regulations). A shielded low-voltage cable is allowed to be as close as 2 inches. Getting closer induces voltage in the data cable, caused by the power cable's magnetic field, which can do bad things to electronic components connected to the data cable.

Getting a Grip

Another tool you'll need is something to attach the pull string to the cable you're pulling. For what they cost, they’re a great addition to the toolkit. Once you've tried a pulling grip, you'll never go back to the crudeness of tape.

For data cable, you'll want a wire mesh grip rather than the heavy-duty set-screw grips used for long pulls of copper power cable.

Wire mesh grips come in a variety of designs for different types of cable. Single weave is good for light cable, while multi-weave is stronger. Grips for small data cables can be very inexpensive, such as these light-duty ones.

The type of pulling eye attached to the grip is another thing to specify.

- Swivel eye: prevents the cable from being twisted

- Flexible eye: helps the cable go around bends

- Breakaway eye: protects delicate cable, such as fiber optic, from being damaged by too much pull tension.

Moving the Wire

Now that we know how the pull line attaches to the cable, let's back up and discuss tools to send the pull line to its destination. The idea is akin to tying a rock to the line and heaving it into the dark in the right general direction, only with more sophistication.

Well-equipped electricians have many low-voltage wire pulling tools at their disposal, such as fish rods with various hooks, telescopic fiberglass poles, and even a magnetic wire pulling system.

If you're leaning more toward an extreme and creative approach, this CO2-powered pull string gun is equipped with a laser sight, two gas cartridges, two darts, and 1200 feet of pull line.

Accessing Ceilings Safely

With your line in place, it's time to start the pull. Or is it? At this point, we have to backtrack again in order to examine two other important pieces of equipment. First of those is a dust containment cart that's both a huge time-saver and a means of keeping the air dust-free in places like hospitals, long-term care facilities, schools, and clean rooms.

Access to ceilings via either the HEPACART® or DUSTBUGGY® dust containment carts is much faster than erecting plastic curtains or other temporary dust-containment measures. Since you'll require access to a ceiling at numerous points along the cable's path in order to install support hardware, the time savings add up rapidly. Either unit takes less than two minutes to set up or take down to move to the next work point. One person can maneuver the cart, which contains everything needed for the job: tools, ladder, and materials.

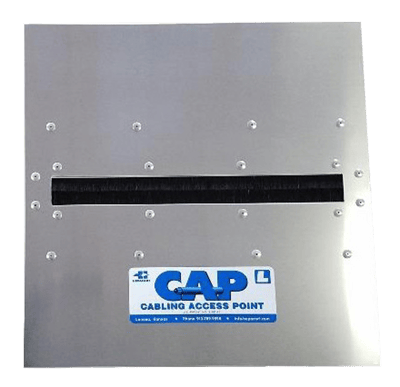

At one end of the pull, you'll need one of our cable access point wire pulling tools (CAP), which install in place of ceiling tile (or two) and let the cable exit (or enter) the ceiling cleanly. Designed with a roller to protect the cable against scrapes and kinks, it also has horsehair bristles to keep dust from falling through with the cable. CAPs come in different sizes and configurations to fit various ceiling openings, cables, and cable bundles. One option even has a helpful window.

Conclusion

We hope this overview was helpful to those of you who identify as electricians or facility managers, as well as anyone who is tasked with pulling cables in a drop ceiling. For detailed information on the products mentioned above, feel free to explore our cable pulling tools.

More reading:

- 101 Guidelines for Fiber Optic Cable Installation

- Installing a CAP: Save Time and Improve Patient Safety

- Benefits of Using Cabling Access Points in Healthcare Facilities

- Cable Pulling Basics: Ceiling Access Tools and Tips

- Cabling Access Point Wire Pulling Tools

- Ceiling Dust Containment Tools

- More related articles