Share this

The Must Have Construction HEPA Filter Equipment

by HEPACART on Oct 24, 2022

Renovations, room upgrades, and other construction projects inevitably create a mess. In a healthcare facility, that mess could have far-reaching effects.

Renovations, room upgrades, and other construction projects inevitably create a mess. In a healthcare facility, that mess could have far-reaching effects.

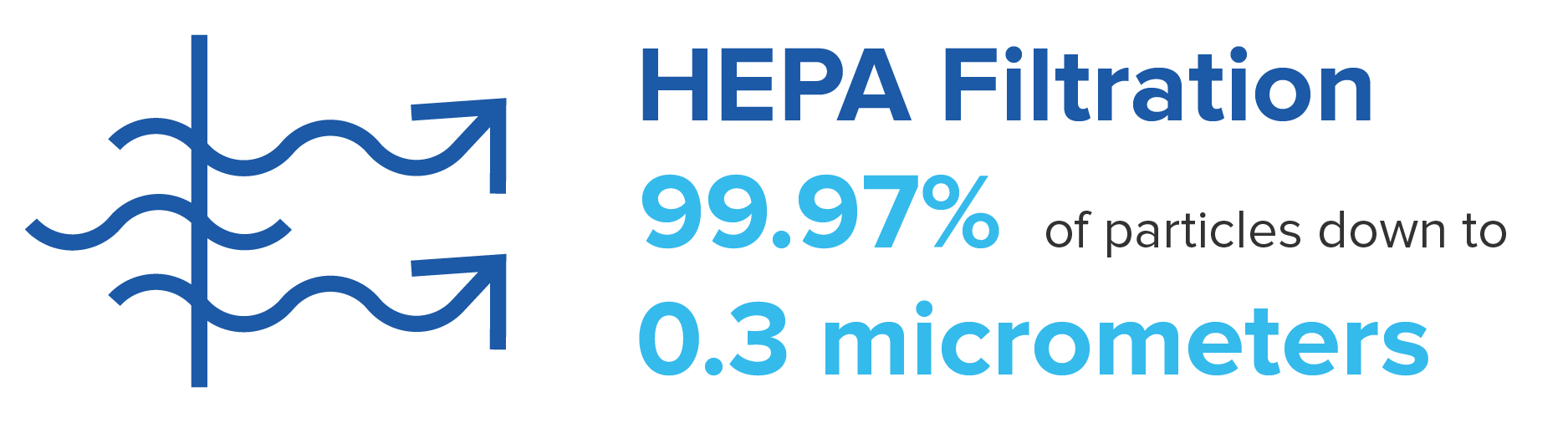

Construction dust not only causes irritation but also creates a vector for airborne pathogens. And unfortunately, standard cleaning and filtration equipment is often insufficient. Many of the dust particles released or created by construction activity are mere microns in size. That means they're small enough to pass through most filters.

A High-Efficiency Particular Air (HEPA) filter traps most airborne particles. A medical-grade filter captures 99.97% of all particles at .03 microns or smaller. Thus, HEPA filter equipment is critical for construction work in hospitals and clinics.

Here's what your healthcare facility can use to maintain (and even improve) indoor air quality.

Why HEPA Filters Are Critical to Healthcare Facilities' Air Quality

As construction dust spreads throughout a building, it can pick up viruses, bacteria, and mold spores. Thus, dust is a major risk factor for the spread of disease, which is already a serious issue in a medical facility. Healthcare-associated Infections (HAIs) are quite common, and circulating dust may allow pathogens to travel even farther.

Renovations or upgrades release dust as ceilings or walls are opened or as semi-permanent structures are moved around. The work itself also creates dust, including paint or drywall particles, sawdust, etc.

Any particles that move out of the workspace may pass into patient areas. A HEPA filter can capture most of these particles, but only if the air passes through it. Ideally, the air is circulated and cleaned within the work area.

Thus, there are two steps to preserving air quality during construction:

- Limit the spread of dust as much as possible. Whenever possible, contain it within the workspace by creating more airflow into the space than out of it.

- Ensure the dust that does become airborne is captured by the HEPA filter and cleaned via carbon cartridges, UV sterilizers, or other sanitation methods.

To achieve these objectives, you may need some or all of the following HEPA-enhanced equipment.

Dust Containment Device

Air moves from areas of high pressure to low pressure. So, the workspace should be lower-pressure than the sensitive patient areas.

A dust containment device uses a negative air machine to limit airflow out of the workspace. This helps prevent particles from spreading into other areas. Projects that involve opening a ceiling or wall often release debris or pathogens that quickly hitchhike on the air.

So, dust containment is critical to preserving indoor air quality (IAQ) and keeping pathogens from spreading. These devices are often combined with HEPA filters in two ways:

- Air that flows out of the workspace first passes through a HEPA filter to remove dust and contaminants.

- As airflow is stronger moving into the space, it's also filtered to catch any microbes that could cling to the construction dust.

Both methods help prevent pathogens from circulating and improve your healthcare facility's IAQ. Instead of passively catching airborne particles, the dust containment approach reduces the number of particles to begin with.

Negative Air Machine Scrubber

Negative Air Machine Scrubber

Air filtration is only part of the picture. While dust containment devices help prevent particles from leaving the space, HEPA filters only work if most of the air passes through them.

A negative air machine helps ensure maximum airflow through the filtration system. So, more airborne particles get trapped and the air quality actually improves.

Medical-grade air scrubbers have a MERV (Minimum Efficiency Reporting Value) rating of at least 16, meaning that it can capture particles as small as .03 microns. They usually feature a high-performance fan that circulates at least 50 cubic feet of air per minute. Thus, the workspace's air is constantly being passed through the HEPA filter.

Many medical-grade scrubbers also contain UV sterilizers to destroy any viruses or bacteria, thereby reducing the risk of HAIs. Carbon filters help remove Volatile Organic Compounds (VOCs) and other pollutants.

Dual Dust-Containment/Air Scrubber

If your project involves an entire room or an area where particles could easily spread to patient spaces, combine the dust containment and air-scrubbing approaches. You have two options:

An anteroom effectively creates a "clean room" where airflow out of the space is limited. The interior's air is heavily filtered upon both entering and exiting. Inside the anteroom, high-powered fans continually draw the air through a scrubber. Negative air machines prevent dust particles from escaping space.

A mobile containment/filtration unit can be set up in any space that's not easily closed off. For example, dust can easily escape if workers are opening a wall or ceiling in the lobby. A mobile unit creates a localized negative airflow for flexible workspaces. They're often equipped with a HEPA filter to capture as many particles as possible on the spot.

Wrapping Up

HEPA filters are a powerful tool for preserving indoor air quality during construction work and limiting the spread of pathogens and pollutants. They're easily integrated into dust containment and air scrubber machines — and combinations thereof!

In any case, take a proactive approach to reduce construction dust and clean your facility's air. HEPA technology makes it much easier to achieve infection control and boost indoor air quality at the same time.