OUR CERTIFICATIONS

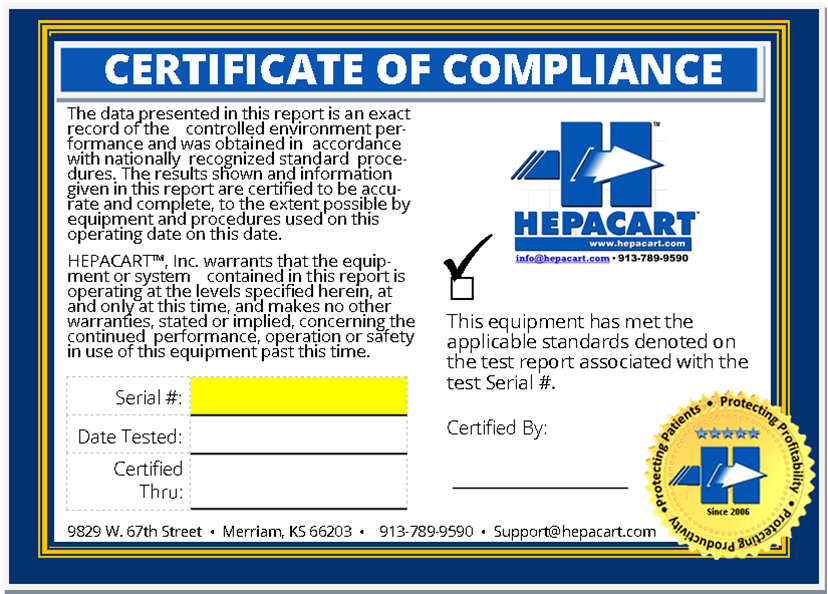

Each product that has a negative air machine with HEPA-Filtration is Certified as a unit with an on-site Controlled Environment Performance Test and Certification Report.

Each unit has been tested in accordance with the following specifications:

1. Manufacturer’s Specifications

2. IEST-RP-CC002.3, Unidirectional Clean Air Dev.

3. ISO 146441-1 Classifications of Air Cleanliness

Each unit has been tested with this equipment:

1. Lighthouse Particle Counter Model # Solair 3100 | Serial # 1300104023

2. ATI Aerosol Generator | Model ATI Series 6 |Serial # 23342

3. EBT™ Balometer | Model # EBT731 | Serial # EBT31304008

4. EBT™ Micromanometer | Model #: EBT731 | Serial # EBT31304008

5. ATI™ Aerosol Photometer |Model #: TDA-2G |Serial # 11708

All of this equipment is tested and recertified on an annual basis.

Each unit has been tested for noise, level and electrical (GFI and Maximum Amps)

Each HEPACART® design has been lab-tested by LMS Technologies, Bloomington, MN.

You can find those results here:Single Pass Filtration Results

Each HEPACART® design has been smoke tested to make sure the air is being contained and filtered.

Verifying acceptable performance concerning airflow and HEPA-filter performance

The following documents are utilized or referenced to perform this certification:1. IEST-RP-CC0034.3: HEPA and ULPA Filter Leak Tests (Institute of Environmental Sciences and Technology)2. ISO 14644-1: Cleanrooms and Associated Controlled Environ-ments—Part 1—Classifications of Air Cleanliness.Air Flow Testing: HEPA-filter air-flow velocities are measured in Cubic Feet per Minute (CFM) with the use of an Air Data Multimeter with the capture cone attachment.

HEPA-Filter Integrity

Emory 3004 (PAO) is utilized as the aerosol challenge material. Distribution is via cold laskin nozzle generation introduced into the upside of the exhaust HEPA-filter. A particle counter is used to scan the HEPA filter. The HEPA-filter and the frame are scanned at a rate not exceeding two inches per second at a distance of approximately one inch from the exit plane of the HEPA-filter.

Particle Count Classification

The HEPA filtered exhaust air needs to meet an ISO 14644 Class 5 environment in an at rest condition.

Current Certification Schedule

Annual recertification of the equipment is due one year from the testing date.